The automated optical inspection (known as AOI) is a practice that has become quite popular over the years for the manufacture of machines that are dedicated to the optical inspection of materials and manufactured parts.

All aspects that are involved in the manufacture of an optical inspection machine are very important, the correct development of each of these aspects will depend on the results of all the inspections and all the operations that will be carried out.

One of the most important processes for the AOI machine manufacturers involves a program that is capable of detecting any failure of the parts that are part of the inspection.

From this program it will be possible to determine if during the process defects will be found and which of these will cause a piece to be discarded because it is not within the standards. The AOI machine manufacturers understand this and for this reason have managed to segment this process in various stages.

It is important that the AOI machines comply with all these steps, in this way the AOI machine manufacturers can assure their clients that each of the processes will be able to completely determine the quality of the parts and materials that are inspected, and in addition to this they will achieve Sort the defective materials and make a statistic of the most common defects.

These are the basic processes that involve a defect detection of a material:

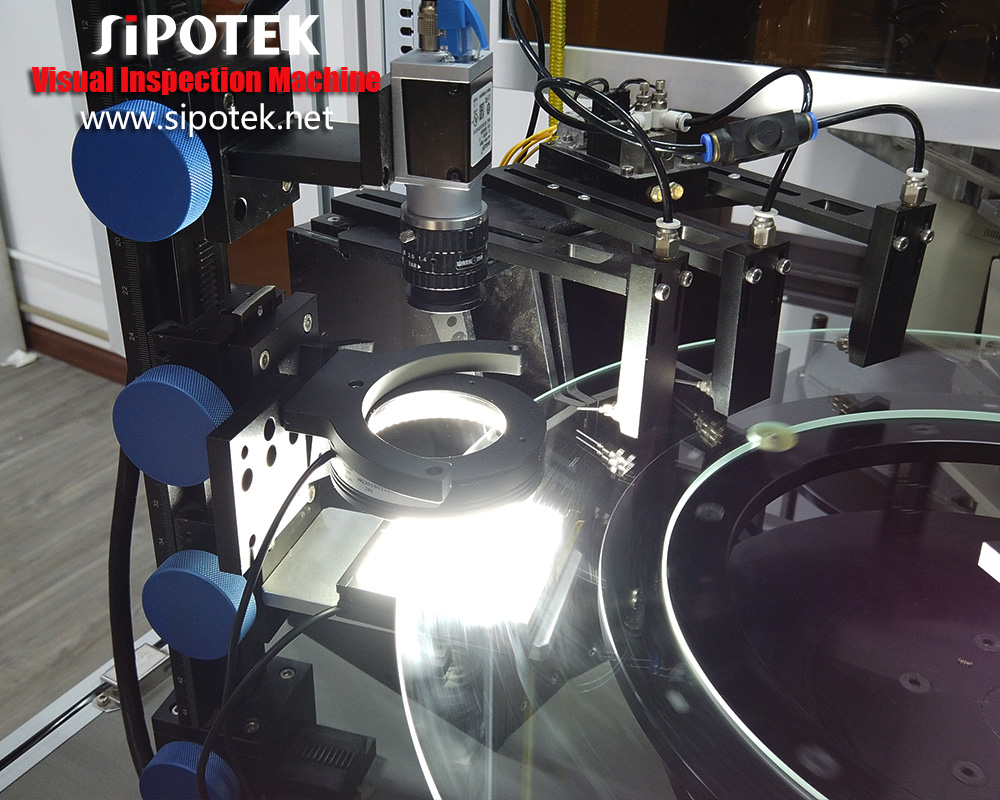

– Location of the part or material to be reviewed: In this first phase, the AOI machine manufacturers must ensure that the machine achieves recognition of the piece to be analyzed. This will be done through the image captured by all the high resolution cameras that they have, all the elements that can modify the image will be considered.

– Separation of the images: Once the program has obtained the images perceived by the cameras, it must be responsible for the segmentation of the images. This separation of the general image will have the purpose of selecting by areas the parts of interest of the component to be reviewed. In this way you can observe manufacturing details individually, in this way you can give a more specific diagnosis regarding the observed faults.

– Organization of the images: Once all the data collected in the phase of the separation of the images is obtained, the remaining elements will be purified, leaving only the piece, which is the fundamental part of the inspection, in this phase it is completely observed the design and the characteristics of the piece, in this phase the comparisons with the image of the ideal piece are included, in this way defects of designs and other characteristics can be detected.

– Optimize the signal: During this part of the process, it is observed how the program performs a kind of filter through which it will completely purge the image, since there are several external factors that can compromise the reality of the image.

– Results of the evaluation: The AOI machine manufacturers always take into account that all the processes performed by the optical inspection machine must be quantified, this is its main function. This is where the pieces are classified.

The AOI machine Price is always a little high, this is because the materials that are needed for its manufacture are of the highest quality.

For more about machine vision inspection system manufacturer,you can pay a visit to sipotek at https://www.sipotek.net

About Shenzhen Sipotek Technology Co., Ltd

Started in 2002, Sipotek Technology is located in Shenzhen in China. The company designs and manufactures visual inspection systems with its avant-garde R&D department and a great experience in artificial vision technologies. The Sipotek Technology staff supports customers 360 degrees, from listening to their requests to the development of ambitious machines for quality control.

For Product Inquiries:

Contact Person: James Yuan

Company: Shenzhen Sipotek Technology Co., Ltd

Tel: 86-755-36994123

Email: info@sipotek.net

Twitter:https://twitter.com/sipotek2019

Website: https://www.sipotek.net

没有评论:

发表评论